LYDIA Voice live at PET FOOD EXPERTS

Get to know the leading voice solution for intralogistics and take a look behind the scenes of the PET FOOD EXPERTS distribution center!

Get to know the leading voice solution for intralogistics and take a look behind the scenes of the PET FOOD EXPERTS distribution center!

Workforce management in logistics with EPG's WFM: Do you know when your warehouse employees are idle? Do you know all the working time agreements you have with your employees? Do you already have a very flexible roster? Are you sure that you are always efficiently allocating your available resources? WFM answers these questions.

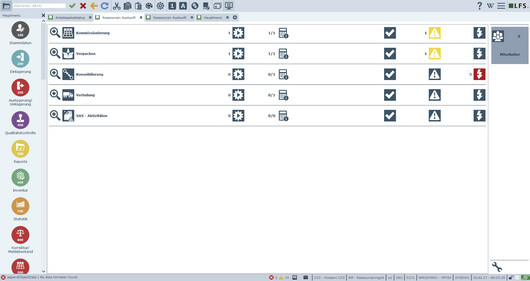

WFM monitors your order volume and your human resources – transparently, clearly and always with the latest information. WFM models the entire order and segments it into the necessary process steps, such as picking, packing and shipping. WFM can also be adapted to your specific process requirements by customizing without substantial effort and uses your human resource and company requirements as the basis for workforce management with shift and duty rosters.

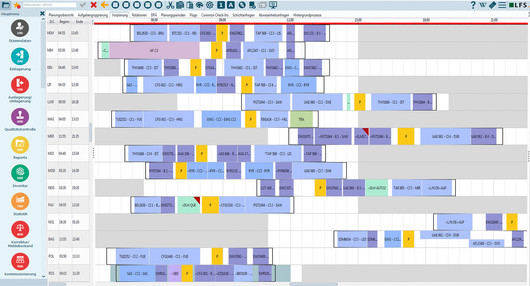

Benefit from accurate planning of all sub-steps and a 100% transparent overview of the processing time and the current status of each order, so you can allocate your human resources efficiently. Potentially critical situations can be identified early on and resolved before they occur. The graphical presentation of current resource utilization gives you an overview at all times, increasing your delivery service level as well.

WFM shows the current utilization of your human resources, making it easy to calculate for the future. You get planning certainty by identifying potential for improvement in the warehouse and optimizing the deployment of your human resources. That gives you a crucial competitive advantage.

For optimum determination of the required capacities, the processing time per sub-step is included in the calculation. The function also uses stored shift rosters and current logon credentials to identify available employees and dynamically visualizes all resource availabilities. WFM works even more dynamically if it knows the order forecasts for the next few days. WFM can then deliver demand-oriented resource planning, which also increases employee satisfaction.